Search: Site This Page

(405) 360-1552

| Ecovac Services / Projects / Railroad / |

CSX Tilford Depot

|

SITE LOCATION: |

Atlanta, Georgia (Railroad site) |

|

PLUME DESCRIPTION: |

Separate-phase hydrocarbons (SPH) present in 13 monitor wells in three separate areas with an aggregate SPH thickness exceeding 54 feet |

|

EFR® RESULTS: |

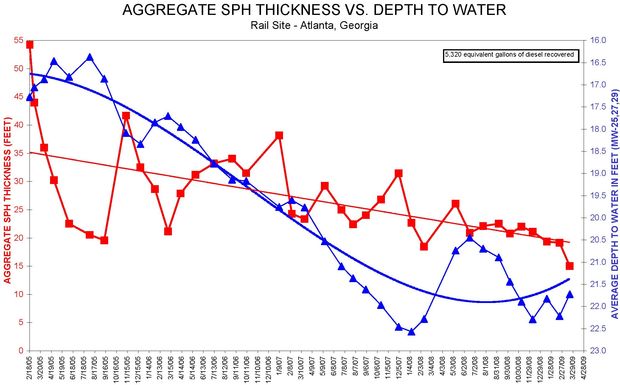

EFR® has been implemented at this site, recovering 5,320 equivalent gallons of diesel fuel, resulting in a 66% reduction in SPH thicknesses |

Background

EcoVac Services was retained to remove SPH from a rail yard in Atlanta, Georgia. Diesel fuel is manifested in 13 monitor wells at this site in three separate areas. The aggregate thickness of the SPH exceeds 54 feet and is present in wells as much as 8.63 feet of SPH present in individual wells.

Treatment Methodology

EcoVac Services was contracted to implement EFR® (Enhanced Fluid Recovery – mobile dual-phase/multi-phase recovery) at this site due to the challenging conditions (i.e. geology/hydrogeology conditions, extent of SPH plume, and limited site access).

EFR® Results

EcoVac Services has implemented a total of 423 hours of EFR® at this site, consisting of 38 EFR® events conducted from April 2004 through February 2009. Despite low permeability conditions that prevail in the saprolite at this site, a total of 5,320 equivalent gallons of diesel fuel have been removed by the EFR® process. Total cost for EFR® has been $146,370, equating to $27.51/equivalent gallon.

Aggregate SPH thicknesses have been reduced by 66%, despite a >6 feet drop in the water table (which generally exacerbates the presence of SPH).

EcoVac Services’ patented SURFAC® process has been proposed for this site to remove the remaining diesel SPH. SURFAC® consists of the combination of dual-phase/multi-phase extraction and surfactant injection.