Search: Site This Page

(405) 360-1552

| Ecovac Services / Projects / Diesel Fuel / |

Nashville, Tennessee

|

SITE LOCATION: |

Nashville, Tennessee |

|

CONTAMINATION: |

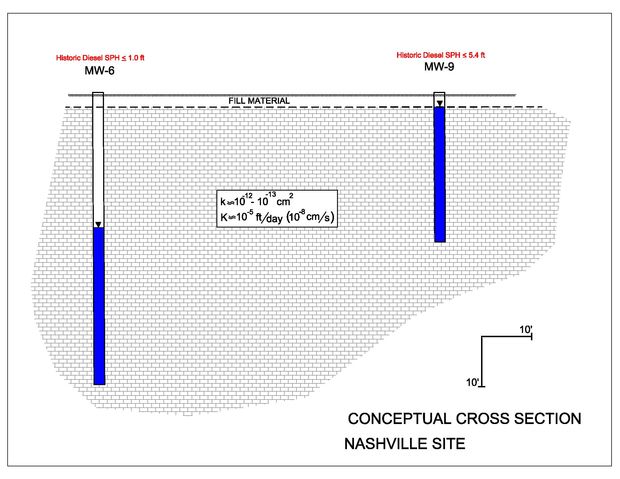

Historically, separate-phase hydrocarbons (SPH) thicknesses up to approximately five feet had been present in two monitor wells |

|

GEOLOGY: |

Fractured Limestone Bedrock |

|

HYDROGEOLOGY: |

Groundwater is present in limestone at approximately 3 to 35 feet below grade. |

|

SURFAC® EFFECTIVENESS: |

SITE CLOSURE |

Background

The subject site was selected by the Tennessee Department of Environment and Conservation to test the effectiveness of EcoVac Services’ patented SURFAC® process and remove gasoline/diesel fuel. Little background information was obtained prior to SURFAC® due to the client’s computer files being destroyed. Mobile-phase extraction events and SPH skimmers had been previously utilized to remove SPH from the site.

The object of EcoVac Services’ patented SURFAC® process was to remove all SPH from the site.

Geology/Hydrogeology

Groundwater is present in limestone at depths ranging from 3 to 35 feet below grade. Limestone is present at approximately 2 feet below grade.

Treatment Methodology

EcoVac Services was contacted to implement SURFAC® at this site due to the challenging subsurface conditions (i.e. fractured limestone bedrock) and the failure of previous remedial activities.

EcoVac Services’ patented SURFAC® process is the combination of dual-phase/multi-phase extraction and surfactant injection. The process described herein is patent-protected and represents the intellectual property of EcoVac Services, Inc.

SURFAC® Pilot Test

A one-day SURFAC® pilot test was conducted at the site to: (1) achieve contaminant removal, (2) reduce the aerial/vertical extent of the plume, (3) locate fractures/joints and depth(s) of contamination for proper placement of the surfactant, (4) determine the surfactant injection volumes/locations/sequence, and (6) determine the duration of the surfactant injection/capture events.

Historically, SPH had been present in two monitor wells ranging up to 5 feet in thickness. The SURFAC® pilot test was conducted at two monitor wells. Stinger (drop tube) depths were increased throughout the event to identify fractures/joints and depth(s) of contamination. Fractures/joints were identified during the test by higher flow rates and lower in-well vacuums at certain stinger depths. Hydrocarbon removal rates increased when these fracture/joints were contacted, indicating these fracture/joints acted as preferential pathways for fuel migration and accumulation in the subsurface. The dewatering of the aquifer during the pilot test exposed “trapped” SPH and mobilized it to MW-9.

SURFAC® Treatment Program

SURFAC® was conducted at the subject site during a one week period in September 2005. The pilot test had mobilized SPH (0.25 feet) into one well prior to SURFAC®. The aquifer was dewatered during SURFAC® to expose the SPH “trapped” in the fractures/joints identified during the pilot test and ensure the injected surfactant came into contact with the SPH. Mobilized SPH was subsequently “captured” with mobile dual-phase/multi-phase extraction.

Results

SITE CLOSURE WAS ACHIEVED.