Search: Site This Page

(405) 360-1552

| Ecovac Services / Projects / Treatability Studies / |

Pine Tar Treatability Study

A treatability study was conducted by EcoVac Services to assess the efficacy of potential remedial approaches at the subject site. A summary of these results are provided below.

TREATABILITY TESTING APPROACH

The intent of this treatability test was to simulate the new remedial approaches suggested by EcoVac Services, utilizing a cosolvent and/or surfactant injection combination. These new approaches will be compared with the previous remedial approach utilized during the pilot injection event at the Former Tunnel Diner site conducted in April 2009.

A soil sample was collected from boring EFR-6 at a depth between eight (8) and ten (10) feet below ground surface (bgs). The soil sample consisted primarily of peat and was relatively uncontaminated. Total petroleum hydrocarbon (TPH) analysis was conducted on the soil using TNRCC Method 1005 and the content of TPH was found 225 milligrams (mg) / kilograms (kg). The soil samples were spiked with site NAPL to at least 20% NAPL residual saturation level (at least 20% of effective porosity was saturated with the NAPL). The NAPL was collected from remediation well EFR-9. Specific gravity of the NAPL was 0.970 and it was relatively non-viscous compared to similar distillates derived from tars. Site groundwater collected from remediation well EFR-14 was also used during the study.

Six remedial approaches were simulated in the column tests, consisting of:

- Previous Injection/Capture (utilized during the April 2009 pilot injection)

Combined with Dual-Phase/Multi-phase Extraction (SOLV-IT®)

-

- 35.5% isopropyl alcohol

- 5.35% commercially available Winsor Type I (solubilizing) surfactant

- 59.15% tap water

- a, b, and c were combined

- Injecate mixture volume = 1.5 pore volumes

- Five (5) post-injection simulated EFR® events

- Proposed Surfactant Injection/Capture Combined with Dual-Phase/

Multi-phase Extraction (SURFAC®)

-

- 4% Winsor Type I (solubilizing) EcoVac Formulated Surfactant (EFS™)

- Surfactant volume = 1.0 pore volume

- Five (5) post-injection simulated EFR® events

- Proposed Cosolvent & Surfactant Injection/Capture Combined with Dual-Phase/

Multi-phase Extraction (SOLV-IT® / SURFAC®)

-

- 100% vegetable derived biosolvent A

- Biosolvent A volume = 0.5 pore volume

- 4% Winsor Type I (solubilizing) EcoVac Formulated Surfactant (EFS™)

- Surfactant volume = 1.0 pore volume

- Five (5) post-injection simulated EFR® events

- Proposed Surfactant Injection/Capture Combined with Dual-Phase/

Multi-phase Extraction (SURFAC®)

-

- 4.35% Winsor Type III (mobilizing) EcoVac Formulated Surfactant (EFS™)

- Surfactant volume = 1.0 pore volume

- Five (5) post-injection simulated EFR® events

- Proposed Cosolvent & Surfactant Injection/Capture Combined with Dual-Phase/

Multi-phase Extraction (SOLV-IT® / SURFAC®)

-

- 100% vegetable derived biosolvent B

- Biosolvent B volume = 0.5 pore volume

- 4% Winsor Type III (mobilizing) EcoVac Formulated Surfactant (EFS™)

- Surfactant volume = 1.0 pore volume

- Five (5) post-injection simulated EFR® events

- Proposed Cosolvent & Surfactant Injection/Capture Combined with

Dual-Phase/Multi-phase Extraction (SOLV-IT® / SURFAC®)

-

- 100% vegetable derived biosolvent B

- Biosolvent B volume = 0.5 pore volume

- 4% Winsor Type I (solubilizing) EcoVac Formulated Surfactant (EFS™)

- Surfactant volume = 1.0 pore volume

- Five (5) post-injection simulated EFR® events

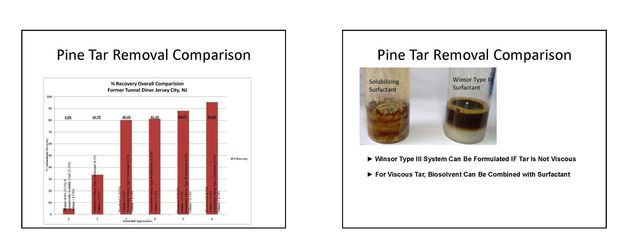

TREATABILITY STUDY RESULTS SUMMARY

Each test result is summarized as follows:

- Previous Injection/Capture Combined with Dual-Phase/

Multi-phase Extraction (SOLV-IT®)

-

- Initial TPH = 78,717 mg/kg

- Final TPH = 74,834 mg/kg

- TPH recovery percent = 4.9%

- NAPL breakthrough during the test – A small amount of NAPL was extracted

- No pressure increase during the injection

- Proposed Surfactant (EFS™) Injection/Capture Combined with Dual-Phase/

Multi-phase Extraction (SURFAC®)

-

- Initial TPH = 144,324 mg/kg

- Final TPH = 95,726 mg/kg

- TPH recovery percent = 33.7%

- NAPL breakthrough during the flushing – A small amount of NAPL was extracted (See the picture below for effluents)

-

- No pressure increase during the injection

- Proposed Cosolvent (Biosolvent A) & Surfactant (EFS™) Injection/Capture Combined with Dual-Phase/Multi-phase Extraction (SOLV-IT® / SURFAC®)

-

- Initial TPH = 146,695 mg/kg

- Final TPH = 28,953 mg/kg

- TPH recovery percent = 80.3%

- NAPL breakthrough during the flushing – A large amount of NAPL was extracted (See the picture below for effluents)

-

- No pressure increase during the injection

- Proposed Surfactant (EFS™) Injection/Capture Combined with Dual-Phase/

Multi-phase Extraction (SURFAC®)

-

- Initial TPH = 131,644 mg/kg

- Final TPH = 46,940 mg/kg

- TPH recovery percent = 81.1%

- NAPL breakthrough during the flushing – A moderate amount of NAPL was extracted (See the picture below for effluents)

-

- No pressure increase during the injection

- Proposed Cosolvent (Biosolvent B) & Surfactant (EFS™) Injection/Capture Combined with Dual-Phase/Multi-phase Extraction (SOLV-IT® / SURFAC®)

-

- Initial TPH = 111,726 mg/kg

- Final TPH = 13,328 mg/kg

- TPH recovery percent = 88.1%

- NAPL breakthrough during the flushing – A Large amount of NAPL was extracted (See the picture below for effluents)

-

- No pressure increase during the injection

- Proposed Cosolvent (Biosolvent B) & Surfactant (EFS™) Injection/Capture Combined with Dual-Phase/Multi-phase Extraction (SOLV-IT® / SURFAC®)

-

- Initial TPH = 117,057 mg/kg

- Final TPH = 5,429 mg/kg

- TPH recovery percent = 95.4%

- NAPL breakthrough during the flushing – A large amount of NAPL was extracted

- Pressure increase was observed after completing surfactant injection