Search: Site This Page

(405) 360-1552

| Ecovac Services / Services / |

Enhanced Fluid Recovery EFR® Dual Phase Extraction Technology.

EcoVac’s Enhanced Fluid Recovery (EFR®) multi phase dual phase extraction technology was invented and developed by co-founder David M. Goodrich, PG. In 1988, Mr. Goodrich was responsible for remediating Underground Storage Tank (UST) sites for Texaco and Atlantic Richfield Petroleum Companies in California and Nevada. Recognizing a need for mobile, inexpensive remediation dual phase extraction technology, he invented EFR® multi phase dual phase extraction.

EFR® multi phase dual phase extraction is a mobile form of high-vacuum multi phase dual phase extraction used to remove separate phase hydrocarbons (SPH) floating on the water table in the subsurface; in other words, areas where fuels have been accidentally released from the UST system, a pipeline, or other surface or underground source.

EFR® multi phase dual phase extraction performs dual phase extraction and removes multiple phases of hydrocarbons (liquid and vapor phase) simultaneously by extracting the fuel, vapors and contaminated groundwater from multiple monitor or recovery wells which have been drilled to define the extent of contamination in the subsurface. EFR® multi phase dual phase extraction has also been highly successful in removing significant contamination on sites where other organic chemicals such as acetone or chlorinated solvents have been released and are present in soil and groundwater.

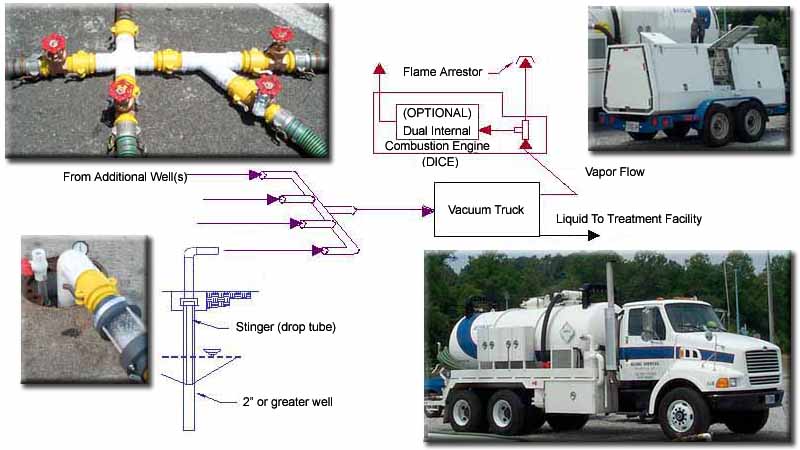

EcoVac’s EFR® multi phase dual phase extraction technology employs a combination of a specially designed truck-mounted vacuum and liquid handling systems integrated with a mobile hydrocarbon vapor treatment system. High vacuum is applied to multiple monitoring or recovery wells with down hole apparatus used to control the fluid elevation in each well. Therefore the vacuum forcefully induces contaminant liquids and vapors to be pulled into the extraction wells from both the vadose zone above the water table and the saturated zone below simultaneously. Extracted contaminant liquids are containerized in the mobile transport unit above ground and harmful volatile vapor emissions are treated by the integrated vapor destruction system.

The effectiveness of EFR® multi phase dual phase extraction has been proven on thousands of UST sites, fuel terminals, refineries, airports, and military installations both in the U.S. and abroad. EcoVac has performed over 10,000 EFR® multi phase dual phase extraction events on greater than 2,500 sites since 1995. EcoVac has provided EFR® multi phase dual phase extraction to over 450 consulting firms and individual clients in 42 states and Puerto Rico.

EcoVac’s pioneering efforts to develop and improve upon the EFR® multi phase dual phase extraction technology led to the invention by co-founder Nick Athens of the patented SURFAC® Surfactant Enhanced Aquifer Remediation, SOLV-IT® LNAPL remediation, and ISCO-EFR® technologies. These highly effective and proven technologies build on the EFR® dual phase extraction method by combining its ability to control the liquid and vapor flow in the subsurface with the introduction of EcoVac Formulated Surfactants (EFS™), cosolvents or biosolvents, and activated chemical oxidants. This is the EcoVac “Combined Technology Approach”.

The Combined Technical Approach (CTA) is a demonstrably powerful tool as it allows a phased approach to whole site remediation. The EFR® dual phase extraction technology provides maximum mass removal of contaminant liquids and vapors in the beginning of the remediation; EFR® multi phase dual phase extraction consequently provides the aquifer testing data which allows for the successful economic integration of the surfactant enhanced mass removal phase (SURFAC®). On sites with viscous NAPL or DNAPL cosolvents or biosolvents (SOLV-IT®) are added to the treatment train and distributed across the zone of contamination with the EFR® multi phase dual phase extraction technology.

EFR® multi phase dual phase extraction has become an accepted technology at the both the State and Federal levels and has been replicated in many areas. EcoVac has the greatest experience and knowledge base of any provider, supplying effective EFR® multi phase dual phase extraction services nationwide. We combine this invaluable remediation experience with our leading edge technologies of SURFAC® Surfactant Enhanced Aquifer Remediation, SOLV-IT® LNAPL Remediation, and ISCO-EFR®.

EFR® multi phase dual phase extraction technology has been implemented in a wide range of hydrogeologic regions throughout the United States(37 states)and Puerto Rico and is an innovative and cost effective alternative for the removal of volatile organic compounds (VOCs) from the subsurface. The EFR® multi phase dual phase extraction process is best described as a mobile version of dual-phase or multi-phase extraction (DPE/MPE) and is represented in Figure 1. The greatest benefits of the EFR® multi phase dual phase extraction process, as well as DPE/MPE technologies, is the ability to simultaneously treat all phases of VOCs while also addressing the entire impacted (unsaturated and saturated) soil column.

EFR® multi phase dual phase extraction technology is a mobile system that is particularly effective in the removal of free product (e.g. gasoline and diesel). EFR® multi phase dual phase extraction technology utilizes high vacuums (with vacuum pumps rated at a maximum of 27 inches of mercury) and high flow rates simultaneously connected to as many as eight monitoring or recovery wells. EFR® multi phase dual phase extraction technology is normally conducted for an eight hour period per event. As much as 2,500 equivalent gallons of gasoline or diesel have been removed during a single eight hour EFR® multi phase dual phase extraction event.

Figure not available...

Figure 1. Generalized Schematic of the EFR® Multi Phase Dual Phase Extraction Process

EFR® multi phase dual phase extraction technology simultaneously removes vapors, free product, and groundwater from the subsurface. It volatilizes adsorbed and free phase VOCs through a process similar to vapor extraction, but with a much higher vacuum and radius of influence. EFR® multi phase dual phase extraction technology is also very unique in that it can treat adsorbed phase VOCs existing within the "smear zone" (i.e. the zone of seasonal or climatic groundwater fluctuation) that act as a continuing source for dissolved phase VOCs. EFR® multi phase dual phase extraction technology dewaters and exposes the smear zone to the effects of "high rate" soil vapor extraction. EFR® multi phase dual phase extraction technology has also been well documented to be effective in the reduction in dissolved phase concentrations. Importantly, EFR® multi phase dual phase extraction technology also introduces oxygen to the vadose and saturated zones, thereby enhancing aerobic biodegradation.

EFR® multi phase dual phase extraction technology is an important tool, particularly for source removal. As such, it is an excellent compliment to risk based corrective action (RBCA) since source materials can be readily removed, thereby potentially allowing a risk based decision to then be rendered resulting in "monitoring only," no further action (NFA), or a reduced size remediation system. EFR® multi phase dual phase extraction technology also possesses obvious applications at sites where rapid remediation is necessary (e.g. real estate transfers, off-site plume migration, emergency response, etc.) and can be introduced at any time during the "life cycle" of a site. EFR® multi phase dual phase extraction technology is a "pay as you go" remediation method that involves no capital cost investment or operation and maintenance (O&M).